Material

| Body | Aluminum ( 5056) | Steel ● | Stainless Steel | ||||

| Finish | Polished | Zinc Plated | Polished | ||||

| Mandrel | Aluminum | Steel | Stainless Steel | Steel ● | Aluminum | Steel | Stainless Steel |

| Finish | Polished | Zinc Plated | Polished | Zinc Plated | Polished | Zinc Plated | Polished |

| Head Type | Dome, CSK, Large Flange | ||||||

Specification

| D1 NOM. |

DRILL NO. &HOLE SIZE |

ART.CODE | GRIP RANGE | L(MAX) | D NOM. |

K MAX. |

P MIN. |

SHEAR LBS |

TENSILE LBS |

||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm |

#30 3.3-3.4 |

SSF41 | 0.020-0.062 | 0.5-1.6 | 0.297 | 7.5 | 0.238" 9.5 |

0.050" 2.1 |

1.06" 27 |

258 1150N |

292 1300N |

| SSF42 | 0.063-0.125 | 1.6-3.2 | 0.360 | 9.1 | |||||||

| SSF43 | 0.126-0.187 | 3.2-4.8 | 0.422 | 10.7 | |||||||

| SSF44 | 0.188-0.250 | 4.8-6.4 | 0.485 | 12.3 | |||||||

| SSF45 | 0.251-0.312 | 6.4-7.9 | 0.547 | 13.9 | |||||||

| SSF46 | 0.313-0.375 | 7.9-9.5 | 0.610 | 15.5 | |||||||

| SSF48 | 0.376-0.500 | 9.5-12.7 | 0.735 | 18.7 | |||||||

| 5/32" 4.0mm |

#20 4.1-4.2 |

SSF52 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.312" 7.9 |

0.065" 1.65 |

1.06" 27 |

380 1700N |

418 1860N |

| SSF53 | 0.126-0.187 | 3.2-4.8 | 0.437 | 11.1 | |||||||

| SSF54 | 0.188-0.250 | 4.8-6.4 | 0.500 | 12.7 | |||||||

| SSF55 | 0.251-0.312 | 6.4-7.9 | 0.562 | 14.3 | |||||||

| SSF56 | 0.313-0.375 | 7.9-9.5 | 0.625 | 15.9 | |||||||

| SSF58 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| 3/16" 4.8mm |

#11 4.9-5.0 |

SSF62 | 0.020-0.125 | 0.5-3.2 | 0.406 | 10.3 | 0.375" 9.5 |

0.080" 2.03 |

1.06" 27 |

540 2400N |

630 2800N |

| SSF63 | 0.126-0.187 | 3.2-4.8 | 0.468 | 11.9 | |||||||

| SSF64 | 0.188-0.250 | 4.8-6.4 | 0.531 | 13.5 | |||||||

| SSF66 | 0.251-0.375 | 6.4-9.5 | 0.656 | 16.7 | |||||||

| SSF68 | 0.376-0.500 | 9.5-12.7 | 0.781 | 19.8 | |||||||

| SSF610 | 0.501-0.625 | 12.7-15.9 | 0.906 | 23.0 | |||||||

| SSF612 | 0.626-0.750 | 15.9-19.1 | 1.026 | 26.1 | |||||||

| 1/4" 6.4mm |

F 6.5-6.6 |

SSF82 | 0.020-0.125 | 0.5-3.2 | 0.445 | 11.3 | 0.500" 12.7 |

0.100" 2.54 |

1.25" 32 |

810 3600N |

900 4000N |

| SSF84 | 0.126-0.250 | 3.2-6.4 | 0.570 | 14.5 | |||||||

| SSF86 | 0.251-0.375 | 6.4-9.5 | 0.695 | 17.7 | |||||||

| SSF88 | 0.376-0.500 | 9.5-12.7 | 0.820 | 20.8 | |||||||

| SSF810 | 0.501-0.625 | 12.7-15.9 | 0.945 | 24.0 | |||||||

| SSF812 | 0.626-0.750 | 15.9-19.1 | 1.070 | 27.2 | |||||||

| SSF814 | 0.751-0.875 | 19.1-22.2 | 1.195 | 30.4 | |||||||

| SSF816 | 0.876-1.000 | 22.2-25.4 | 1.320 | 33.5 | |||||||

Application

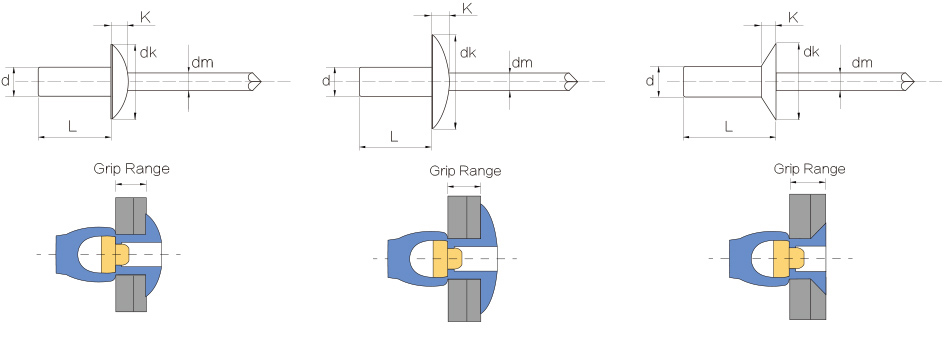

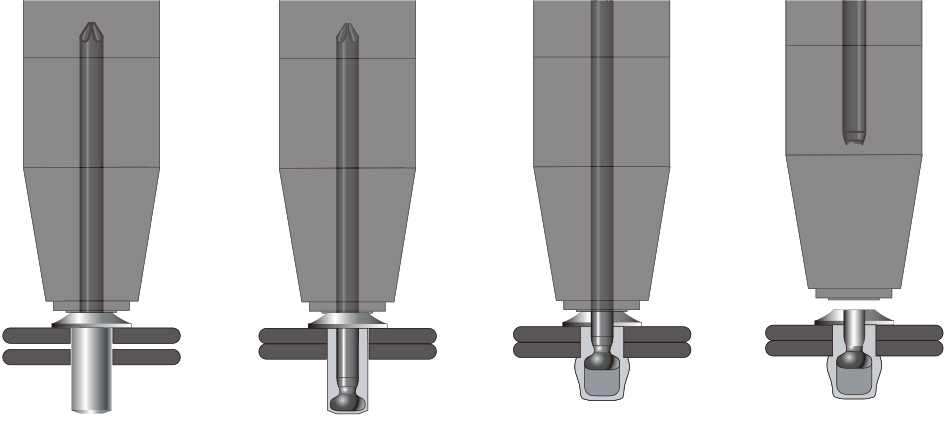

Sealed type blind rivet have the function of sealing, and are generally used on parts with sealing requirements, while open type blind rivet have no sealing function. Closed end blind rivet are core pulling nails with completely closed nail caps, which do not leak air or water, and can be applied to the connection environment with sealing requirements. Raw materials include: Aluminum,steel,stainless steel, with dimensions of 2.4mm, 3.0mm, 3.2mm, 4.0mm, 4.8mm, 5.0mm, 6.0mm, 6.4mm. The types include: flat round head,dome head,countersunk head and large flange head. For more than 30 years, wodecy fastener has been focusing on the R&D and manufacturing of closed and open end pop rivet. It can produce all kinds of closed and open end blind rivet according to German standard DIN 7337, American standard IFI 114,IFI 126, national standard GB and international standard ISO.Wodecy riveting system closed and open type rivets can be customized, such as sample customization, drawing customization, specification customization, material customization, etc.

Differences between open type blind rivets and closed type blind rivets

1. As far as the scope of application is concerned, open type pop rivets are common pop rivets, among which open type round head pop rivets are widely used.

2. In terms of performance: closed blind rivet is a kind of blind rivet with completely closed nail cap, which will not leak air or water, and can be applied to the connection environment with sealing requirements. It has the function of sealing and is generally used on the parts with sealing requirements, while the open type has no sealing function.

3. For the appearance of rivets, open type rivets are open at the front end. The closed rivet is closed at the front section.