Material

| Body | Steel |

| Finish | Zinc Plated |

| Mandrel | Steel |

| Finish | Zinc Plated |

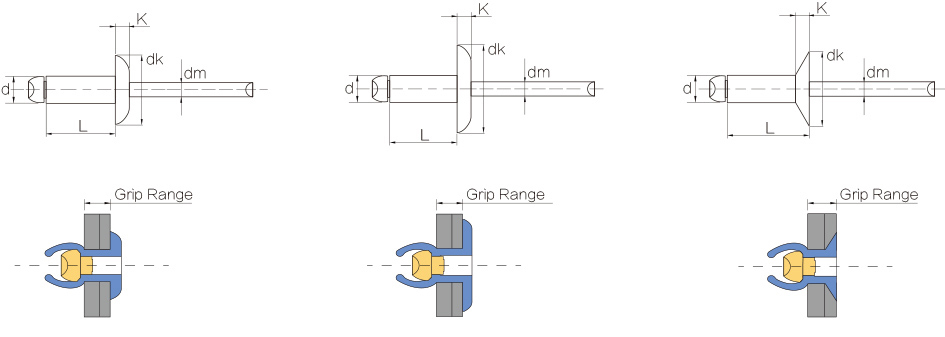

| Head Type | Dome, CSK, Large Flange |

Specification

| D1 NOM. |

DRILL NO. &HOLE SIZE |

ART.CODE | GRIP RANGE | L(MAX) | D NOM. |

K MAX. |

P MIN. |

SHEAR LBS |

TENSILE LBS |

||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4mm |

#41 2.5-2.6 |

SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 |

0.032" 0.81 |

1.00" 25.4 |

130 580N |

170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm |

#30 3.3-3.4 |

SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 |

0.040" 1.02 |

1.06" 27 |

260 1160N |

310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| SS48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm |

#20 4.1-4.2 |

SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 |

0.050" 1.27 |

1.06" 27 |

370 1650N |

470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| SS58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| SS510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm |

#11 4.9-5.0 |

SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 |

0.060" 1.52 |

1.06" 27 |

540 2400N |

680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| SS68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0.876-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm |

F 6.5-6.6 |

SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 |

0.080" 2.03 |

1.25" 32 |

1000 4450N |

1240 5520N |

| SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| SS812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| SS816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Application

steel open end blind rivets not only ease to use, high efficiency, low noise, can reduce labor intensity and other characteristics , but also connections tightness. Steel rivets can be divided into a dome head rivet, countersunk rivets and large flange head rivet. The tensile and shear strength of the steel blind rivets is much more higher than standard aluminum rivets. It is widely used in industrial, can meet the needs of high strength request.

The problems and reasons when using the pop rivet:

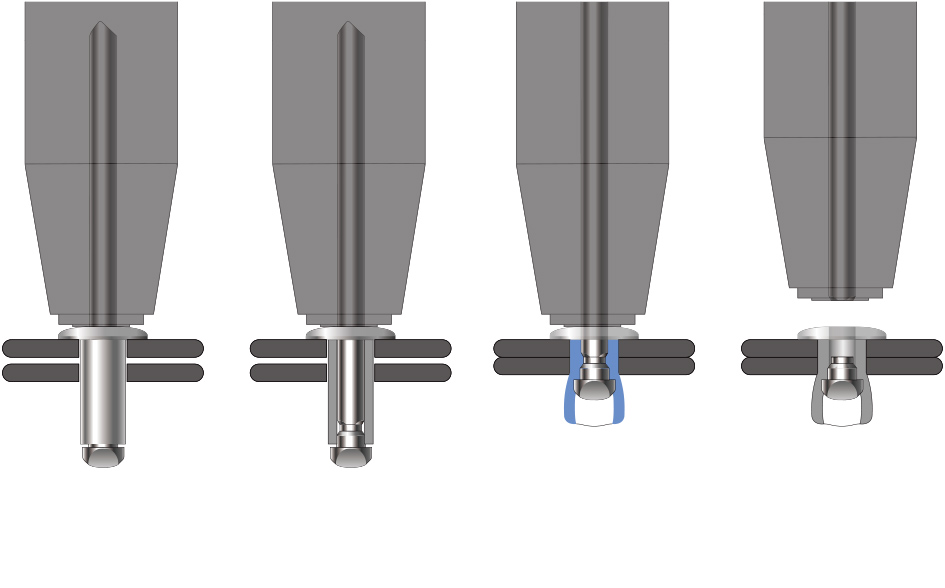

4.The pop rivet is pulled through: The rivet mandrel is fully pulled out of the rivet, and the mandrel is broken. After the riveting, leave empty holes in the rivet.

The reasons for pulling through are: too much rivet mandrel tension; small diameter of mandrel caps; soft riveting materials; the surface of the inner hole is too lubricated.

5.Jump head or drum insufficient: When pulling rivets, the rivet core pops up completely, or the rivet does not swell.

The reasons for this phenomenon are: the tensile force control is too low when the nail core is made; the riveting body is high (uneven annealing);

6. Relax after riveting: After riveting, the riveting body is loose in the workpiece hole.