Material

| Body | Aluminum ( 5056) | Steel | Stainless Steel ● | ||||

| Finish | Polished | Zinc Plated | Polished | ||||

| Mandrel | Aluminum | Steel | Stainless Steel | Steel | Aluminum | Steel | Stainless Steel ● |

| Finish | Polished | Zinc Plated | Polished | Zinc Plated | Polished | Zinc Plated | Polished |

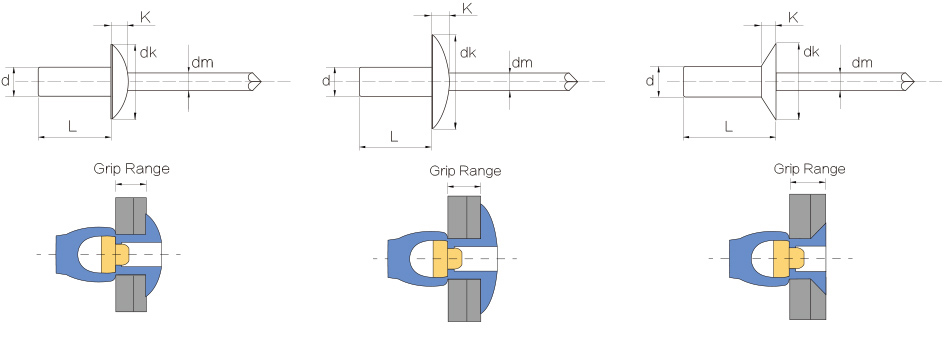

| Head Type | Dome, CSK, Large Flange | ||||||

Specification

| D1 NOM. |

DRILL NO. &HOLE SIZE |

ART.CODE | GRIP RANGE | L(MAX) | D NOM. |

K MAX. |

P MIN. |

SHEAR LBS |

TENSILE LBS |

||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm |

#30 3.3-3.4 |

BBF-S41 | 0.020-0.062 | 0.5-1.6 | 0.297 | 7.5 | 0.238" 6.0 |

0.050" 1.27 |

1.06" 27 |

400 1780N |

450 2000N |

| BBF-S42 | 0.063-0.125 | 1.6-3.2 | 0.360 | 9.1 | |||||||

| BBF-S43 | 0.126-0.187 | 3.2-4.8 | 0.422 | 10.7 | |||||||

| BBF-S44 | 0.188-0.250 | 4.8-6.4 | 0.485 | 12.3 | |||||||

| BBF-S45 | 0.251-0.312 | 6.4-7.9 | 0.547 | 13.9 | |||||||

| BBF-S46 | 0.313-0.375 | 7.9-9.5 | 0.610 | 15.5 | |||||||

| BBF-S48 | 0.376-0.500 | 9.5-12.7 | 0.735 | 18.7 | |||||||

| 5/32" 4.0mm |

#20 4.1-4.2 |

BBF-S52 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.312" 7.9 |

0.065" 1.65 |

1.06" 27 |

700 3120N |

800 3560N |

| BBF-S53 | 0.126-0.187 | 3.2-4.8 | 0.437 | 11.1 | |||||||

| BBF-S54 | 0.188-0.250 | 4.8-6.4 | 0.500 | 12.7 | |||||||

| BBF-S55 | 0.251-0.312 | 6.4-7.9 | 0.562 | 14.3 | |||||||

| BBF-S56 | 0.313-0.375 | 7.9-9.5 | 0.625 | 15.9 | |||||||

| BBF-S58 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| 3/16" 4.8mm |

#11 4.9-5.0 |

BBF-S62 | 0.020-0.125 | 0.5-3.2 | 0.406 | 10.3 | 0.375" 9.5 |

0.080" 2.03 |

1.06" 27 |

850 3790N |

900 4010N |

| BBF-S63 | 0.126-0.187 | 3.2-4.8 | 0.468 | 11.9 | |||||||

| BBF-S64 | 0.188-0.250 | 4.8-6.4 | 0.531 | 13.5 | |||||||

| BBF-S66 | 0.251-0.375 | 6.4-9.5 | 0.656 | 16.7 | |||||||

| BBF-S68 | 0.376-0.500 | 9.5-12.7 | 0.781 | 19.8 | |||||||

| BBF-S610 | 0.501-0.625 | 12.7-15.9 | 0.906 | 23.0 | |||||||

| BBF-S612 | 0.626-0.750 | 15.9-19.1 | 1.026 | 26.1 | |||||||

| 1/4" 6.4mm |

F 6.5-6.6 |

BBF-S82 | 0.020-0.125 | 0.5-3.2 | 0.445 | 11.3 | 0.500" 12.7 |

0.100" 2.54 |

1.25" 32 |

1348 6000N |

1797 8000N |

| BBF-S84 | 0.126-0.250 | 3.2-6.4 | 0.570 | 14.5 | |||||||

| BBF-S86 | 0.251-0.375 | 6.4-9.5 | 0.695 | 17.7 | |||||||

| BBF-S88 | 0.376-0.500 | 9.5-12.7 | 0.820 | 20.8 | |||||||

| BBF-S810 | 0.501-0.625 | 12.7-15.9 | 0.945 | 24.0 | |||||||

| BBF-S812 | 0.626-0.750 | 15.9-19.1 | 1.070 | 27.2 | |||||||

| BBF-S814 | 0.751-0.875 | 19.1-22.2 | 1.195 | 30.4 | |||||||

| BBF-S816 | 0.876-1.000 | 22.2-25.4 | 1.320 | 33.5 | |||||||

Application

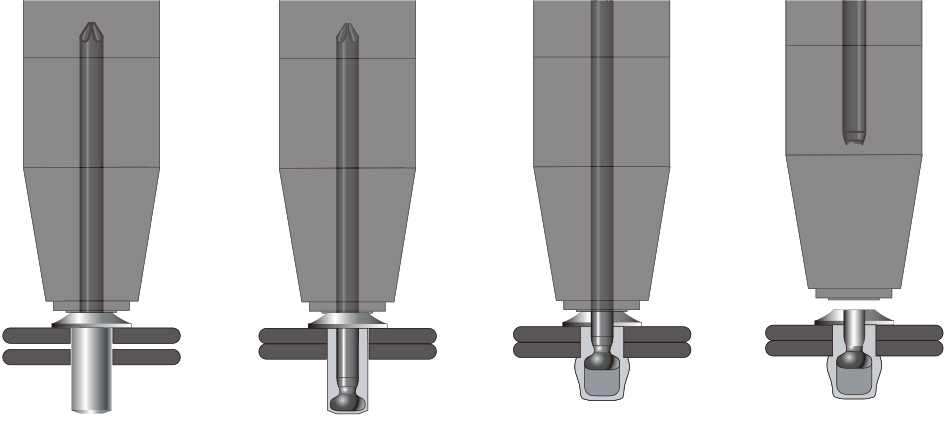

Sealed Type Rivet is specially designed for wrapping the nail head after riveting, so it does not rust. The closed end blind rivet is very suitable for various applications with waterproof requirements. This type rivet has high shear force, vibration resistance and high pressure resistance.

Sealed type blind rivets are suitable for the riveting occasions where high load and certain sealing performance are required. Closed type pop rivets are widely used in buildings, automobiles, ships, aircraft, machines, electrical appliances, furniture and other products.

Closed pop rivet is a unique rivet body design. This kind of pop rivet has a solid core tail structure to prevent steam and liquid around the rivet body from passing through the rivet body. In addition, the tensile strength of closed blind rivets is 20% higher than that of open rivets of the same specification. Another important point is that these closed type pop rivets can ensure that 100% of the rivet heads will not fall off, which makes them widely used in electronic and electrical equipment. Wodecy closed type blind rivets can be provided with dome head, countersunk head and large flange head. In terms of material selection, there are various combinations of aluminum/steel, aluminum/aluminum, aluminum/ steel, aluminum/ stainless steel, stainless steel/stainless steel, steel/steel, etc.

Dome head rivet is the most widely used, and the size of the open type blind rivet is; 4.0mm, 4.8mm, 5mm, 6.4mm.

The closed type blind rivet has a sealing effect. It is generally used on the components that require sealing requirements, and the open type rivet has no sealing function. The closed type pop rivet is a completely closed core rivet. Or leakage can be applied to a connected environment with sealing requirements.

The dimensions of closed rivets are: 3/32",1/8",5/32",3/16",1/4"