Excellent quality Steel Monobolt Pop Rivets - Aluminium with Aluminum Mandrel Open Type Blind Rivet – Fixpal Detail:

Material

| Body | Aluminum(5050 5052 5056 5154) | (AL Mg 1%-1.5%, 2%-2.5% ,3%-3.5%,5%) | ||

| Finish | Polished | RAL Colour Painted | ||

| Mandrel | Aluminum ● | Steel | Stainless Steel | |

| Finish | Polished ● | Zinc Plated | Polished | |

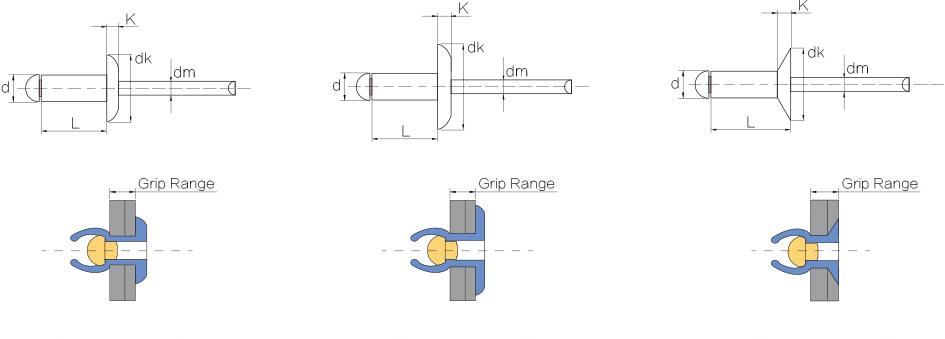

| Head Type | Dome, CSK, Large Flange | |||

Specification

| D1 NOM. |

DRILL NO. &HOLE SIZE |

ART.CODE | GRIP RANGE | L(MAX) | D NOM. |

K MAX. |

P MIN. |

SHEAR LBS |

TENSILE LBS |

||

| INCH | MM | INCH | MM | ||||||||

| 3/32″ 2.4mm |

#41 2.5-2.6 |

AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188″ 4.8 |

0.032″ 0.81 |

1.00″ 25.4 |

70 310N |

80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8″ 3.2mm |

#30 3.3-3.4 |

AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250″ 6.4 |

0.040″ 1.02 |

1.06″ 27 |

120 530 N |

150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32″ 4.0mm |

#20 4.1-4.2 |

AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312″ 7.9 |

0.050″ 1.27 |

1.06″ 27 |

190 850 N |

230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16″ 4.8mm |

#11 4.9-5.0 |

AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375″ 9.5 |

0.060″ 1.52 |

1.06″ 27 |

260 1160 N |

320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4″ 6.4mm |

F 6.5-6.6 |

AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500″ 12.7 |

0.080″ 2.03 |

1.25″ 32 |

460 2050 N |

560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Application

Our full aluminum open end rivet uses high quality aluminum alloy wires. After the riveting, It will never rust. compared with ordinary rivets, the rivet intensity is low, so it is suitable for connected the soft material.Aluminum pop rivets can be divided into a dome head rivet,countersunk rivets and large flange head rivet.And the aluminum alloy material have multi choice of alu mg 2% 2.5% 3.5% and 5%(5052 5154 5056).

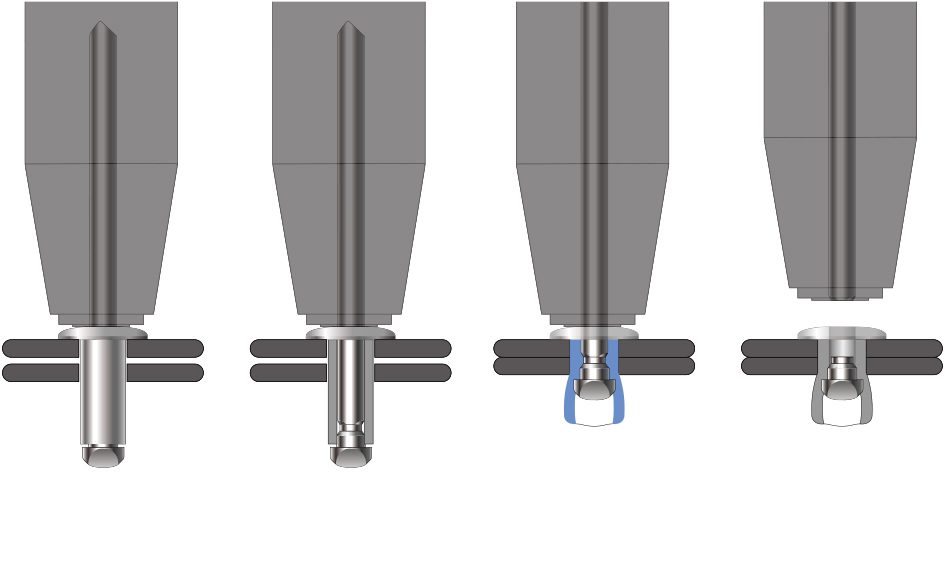

Fixpal open type pop rivets have the advantages of easy operation, excellent riveting, beautiful appearance, high physical properties. Perfect choice of single -sided riveting.Aluminum pop rivets can be widely used in various vehicles, vessels, machinery manufacturing, electronics, instrumentation, food machinery, medical equipment, construction, decoration and other fastening areas.

The problems and reasons when using the blind rivet:

1. Burrs: After riveting, the breaked mandrel with burrs pass through the rivet holes; or the riveting holes protrudes from the outside to form a spatula burr.

The cause of the burrs: the diameter of the mandrel is small; the rivet material is soft; the drilling hole diameter of the workpiece is too large; the muzzle specifications of the rivet gun are too large;

2. The nail head falls off: After the rivet is pulled, the core rivet head cannot be wrapped and falls off from the rivet.

The reasons for falling the rivet head of the core are: the diameter of the nail cap is too large; the rivet is shorter, and the rivet thickness does not match.

3. the rivet cracking: After the riveting, the rivet is pulsed or completely ruptured.

The reasons for the cracking of the rivet are: excessive hardness after riveting annealing or unheated treatment, the nail core hat is too large.

Product detail pictures:

Related Product Guide:

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Excellent quality Steel Monobolt Pop Rivets - Aluminium with Aluminum Mandrel Open Type Blind Rivet – Fixpal, The product will supply to all over the world, such as: India, San Diego, Paraguay, We now have to continue to uphold the quality, detailed, efficient business philosophy of honest, responsible, innovativespirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.

-

2022 High quality Threaded Rivet Nuts - Flat H...

-

OEM/ODM Manufacturer Aluminium Countersunk Rive...

-

Hot-selling Blind Rivets Manufacturer - Alumin...

-

High definition Steel Pop Rivet - Aluminum wit...

-

Wholesale Price Aluminum Bulb Pop Rivet - Stai...

-

100% Original 6mm Pop Rivets - Aluminum with S...