Material

| Body | Aluminum ( 5056) ● | Steel | Stainless Steel | ||||

| Finish | Polished | Zinc Plated | Polished | ||||

| Mandrel | Aluminum | Steel ● | Stainless Steel | Steel | Aluminum | Steel | Stainless Steel |

| Finish | Polished | Zinc Plated | Polished | Zinc Plated | Polished | Zinc Plated | Polished |

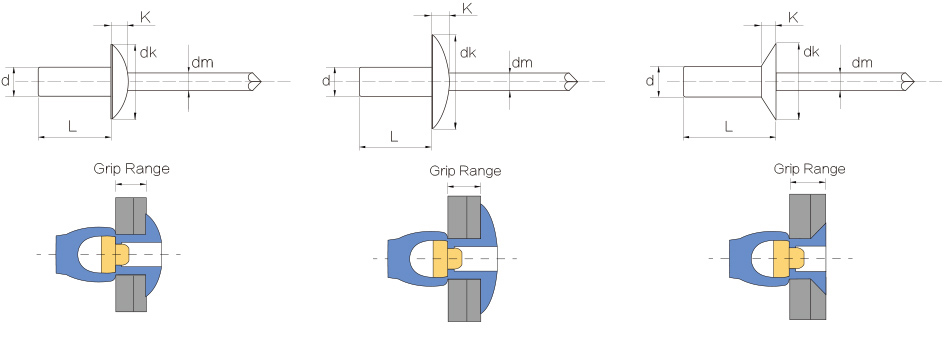

| Head Type | Dome, CSK, Large Flange | ||||||

Specification

| D1 NOM. |

DRILL NO. $HOLE SIZE |

ART.CODE | GRIP RANGE | L(MAX) | D NOM. |

K MAX. |

P MIN. |

SHEAR LBS |

TENSILE LBS |

||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm |

#30 3.3-3.4 |

ASF41 | 0.020-0.062 | 0.5-1.6 | 0.297 | 7.5 | 0.238" 6.0 |

0.050" 1.27 |

1.06" 27 |

240 1070N |

280 1250N |

| ASF42 | 0.063-0.125 | 1.6-3.2 | 0.360 | 9.1 | |||||||

| ASF43 | 0.126-0.187 | 3.2-4.8 | 0.422 | 10.7 | |||||||

| ASF44 | 0.188-0.250 | 4.8-6.4 | 0.485 | 12.3 | |||||||

| ASF45 | 0.251-0.312 | 6.4-7.9 | 0.547 | 13.9 | |||||||

| ASF46 | 0.313-0.375 | 7.9-9.5 | 0.610 | 15.5 | |||||||

| ASF48 | 0.376-0.500 | 9.5-12.7 | 0.735 | 18.7 | |||||||

| 5/32" 4.0mm |

#20 4.1-4.2 |

ASF52 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.312" 7.9 |

0.065" 1.65 |

1.06" 27 |

350 1560N |

480 2140N |

| ASF53 | 0.126-0.187 | 3.2-4.8 | 0.437 | 11.1 | |||||||

| ASF54 | 0.188-0.250 | 4.8-6.4 | 0.500 | 12.7 | |||||||

| ASF55 | 0.251-0.312 | 6.4-7.9 | 0.562 | 14.3 | |||||||

| ASF56 | 0.313-0.375 | 7.9-9.5 | 0.625 | 15.9 | |||||||

| ASF58 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| 3/16" 4.8mm |

#11 4.9-5.0 |

ASF62 | 0.020-0.125 | 0.5-3.2 | 0.406 | 10.3 | 0.375" 9.5 |

0.080" 2.03 |

1.06" 27 |

500 2230N |

690 3070N |

| ASF63 | 0.126-0.187 | 3.2-4.8 | 0.468 | 11.9 | |||||||

| ASF64 | 0.188-0.250 | 4.8-6.4 | 0.531 | 13.5 | |||||||

| ASF66 | 0.251-0.375 | 6.4-9.5 | 0.656 | 16.7 | |||||||

| ASF68 | 0.376-0.500 | 9.5-12.7 | 0.781 | 19.8 | |||||||

| ASF610 | 0.501-0.625 | 12.7-15.9 | 0.906 | 23.0 | |||||||

| ASF612 | 0.626-0.750 | 15.9-19.1 | 1.026 | 26.1 | |||||||

| 1/4" 6.4mm |

F 6.5-6.6 |

ASF82 | 0.020-0.125 | 0.5-3.2 | 0.445 | 11.3 | 0.500" 12.7 |

0.100" 2.54 |

1.25" 32 |

900 4000N |

1100 4890N |

| ASF84 | 0.126-0.250 | 3.2-6.4 | 0.570 | 14.5 | |||||||

| ASF86 | 0.251-0.375 | 6.4-9.5 | 0.695 | 17.7 | |||||||

| ASF88 | 0.376-0.500 | 9.5-12.7 | 0.820 | 20.8 | |||||||

| ASF810 | 0.501-0.625 | 12.7-15.9 | 0.945 | 24.0 | |||||||

| ASF812 | 0.626-0.750 | 15.9-19.1 | 1.070 | 27.2 | |||||||

| ASF814 | 0.751-0.875 | 19.1-22.2 | 1.195 | 30.4 | |||||||

| ASF816 | 0.876-1.000 | 22.2-25.4 | 1.320 | 33.5 | |||||||

Application

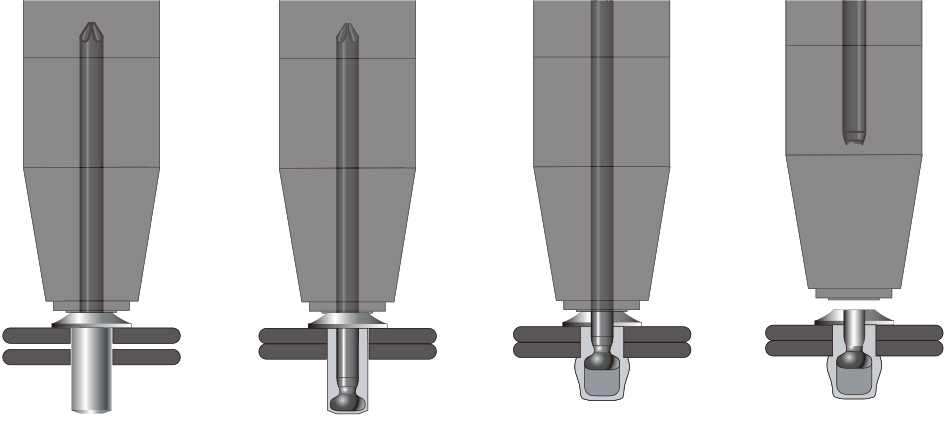

The pop rivet is a kind of rivet used for single-sided riveting, but it must be riveted with a special tool - rivet gun (manual, electric). This kind of rivet is especially suitable for the riveting occasions where it is inconvenient to use ordinary rivets (which must be riveted from both sides), so it is widely used in buildings, automobiles, ships, aircraft, machines, electrical appliances, furniture and other products. Among them, the open type round head pop rivets are the most widely used, the countersunk head pop rivets are suitable for the riveting occasions where smooth performance is required, and the closed type pop rivets are suitable for the riveting occasions where high load and certain sealing performance are required.

Sealed Type Rivet is specially designed for wrapping the nail head after riveting, so it does not rust. The closed end blind rivet is very suitable for various applications with waterproof requirements. This type rivet has high shear force, vibration resistance and high pressure resistance.

Tips for blind rivets Select:

The drilling hole size of the rivet is min+0.1 max+0.2.

The total thickness of the workpiece is generally 45% - 65% of the rivet length It is better not to exceed 60%. In addition, too short working length is also troublesome. It is recommended that 50% - 60% prevail in general If the rivet length is too long, the rivet pier head is too large, and the rivet rod is easy to bend; If the rivet length is too short, the pier thickness is insufficient, and the rivet head molding is incomplete, affecting the strength and tightness. It is not good if the rivet length is too long or too short. Only the proper length can achieve the best riveting effect. For example, if the total thickness of two or more workpieces is 6mm, the rivet length should be 9.23 -- 13.3 mm. In this case, it is better to use the 12mm long rivet.

-

Aluminium with Steel Mandrel Open Type Blind Rivet

-

High Strength Structural Blind Rivets Stainless...

-

Aluminium with Aluminum Mandrel Open Type Blind...

-

Hand Rivet Nut Gun Manual Rivet Nuts Tool Series

-

Thin Head (Reduced Head) Hex Body Open End Rive...

-

Stainless Steel with Stainless Steel Mandrel La...